cadmeister-thai@uelthai.co.th

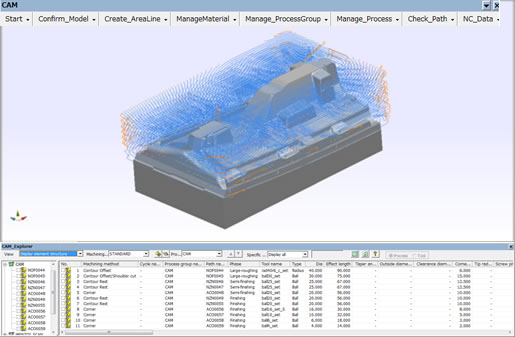

CADmeister/CAM provides operational environments for skillful expert users or beginners.

It can constitute a CAD/CAM integrated system if it is operated in conjunction with dedicated mold/die modeling functions such as CADmeister MOLD and CADmeister PRESS.

Thus, it can create efficiently machining-center (M/C) machining data of high quality.

The basic functions of CAM are expressed in easy-to-understand characters for all users. The user-friendly menus are structured in the same way as in the process for data creation.

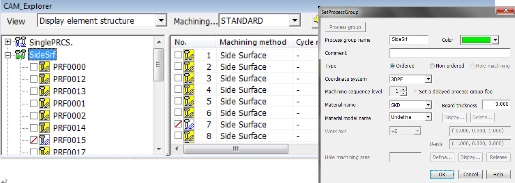

CAM Explorer enables users to manage multiple phases for machining dies/molds through the use of a tree structure. It enables efficient management of phases in accordance with the individual purposes.

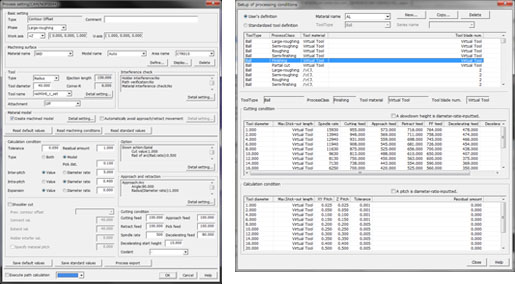

The palette window below for setting phases is capable of automatically saving various types of parameters that have been used for the previous machining of each path.

Also, cutting conditions (expressed in the form of parameters) that correspond to the cutting materials and cutting tools can be saved as control values or result values during the phases of machining.

Thus, user's own expertise can be saved and accumulated together with the relevant operations of individual phases.

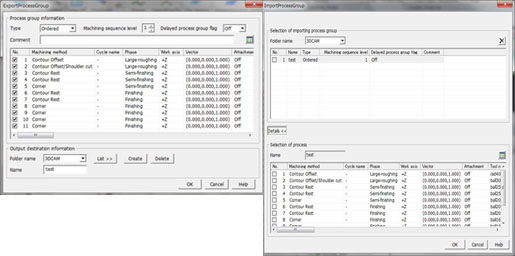

Phases of machining and process schedules can be saved and imported into a machining database, provided that they have been standardized.

Paths can be created by simply entering the minimum necessary inputs, provided that process schedules have been standardized and templatized.

Thus, work hours can be significantly shortened and path quality can be homogenized.

UEL (Thailand) Co.,Ltd.