cadmeister-thai@uelthai.co.th

Full-Mold CAM supports the full-mold processing of a Structure (ferrous die of accepting a press die 'Insert') through the use of 3D solid models.

This tool reduces delivery periods and costs and improves mold quality by executing the commands dedicated for the full-mold processing of a Structure.

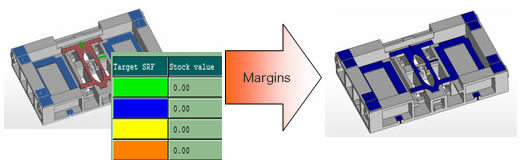

They include commands for examining margins for cutting, checking sectionally split shapes, and calculating paths per slice surface.

Margins are automatically considered and embedded into solid models, upon specifying a margin amount for each shape attribute or for each element color. This will prevent margins from dropping out of consideration.

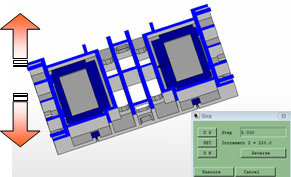

The positions for sectional split can be confirmed by checking the sectional split in real time, before executing the command of division.

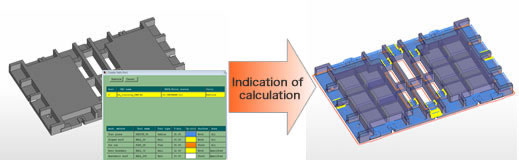

The capability of automatic understanding of shapes helps users by saving the trouble of specifying each processing area when executing commands for path calculation such as: processing flat surfaces, tilting surfaces, and curved surfaces. Relevant paths for the shape can be calculated by indicating any shape.

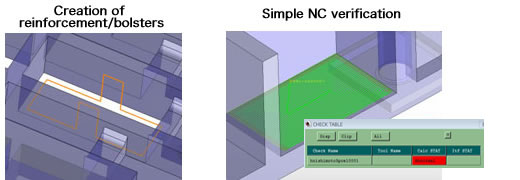

There is a feature for creating bolsters which keep the strength of material when machining the external side. Also, there is a simple NC verification function that automatically removes the portions where interferences are caused by a tool holder.

This capability detects and imports the attributes that correspond to each element color when importing CATIA v 5 data. The imported attributes can be used in order to simplify the process of creating margins and execute the command for automatic and collective calculation of paths.

UEL (Thailand) Co.,Ltd.