cadmeister-thai@uelthai.co.th

CAM-ATTRIBUTE automatically creates and standardizes machining data on the basis of the assigned 2D/3D machining data and geometric information for holing.

Also, standardized machining data can be automatically created, provided that 3D Pocket Machining attributes that have been assigned.

Standardized machining data can be created on the basis of various types of data such as solid models and drawings of an upstream phase and machining data (CSV) files for holing.

They can be further efficiently created if CAM-ATTRIBUTE is operated in conjunction with CADmeister MOLD.

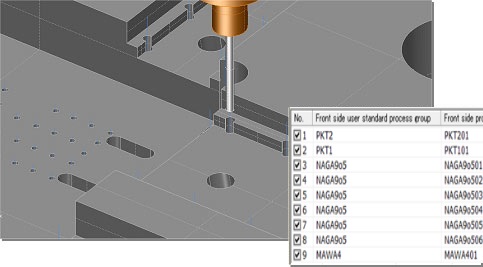

Automatic attribute settings for 2D/3D geometrical shapes

Assignment of machining attributes to the data of hole positions and Pocket shapes that have been imported from machining information (CSV) files

Capability of importing machining attributes that have been assigned to CADmeister MOLD (support for mold designers)

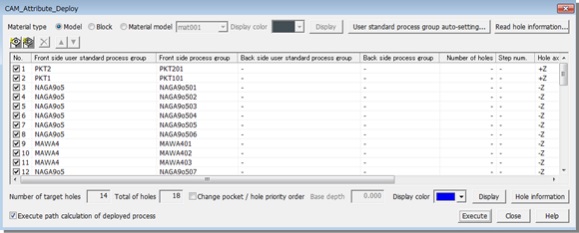

Calculations for machining phases and paths are collectively made on the basis of CAM attribute data.

It is possible to make efficient operations in a single palette window: confirmation of machining results, and management and edit of attribute information.

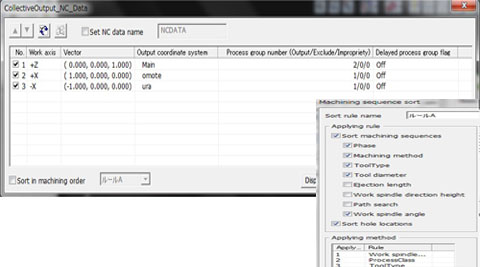

Machining phases can be automatically grouped by direction without considering a machining axis.

User's own machining sequences can be optimized pursuant to situation-specific sorting rules.

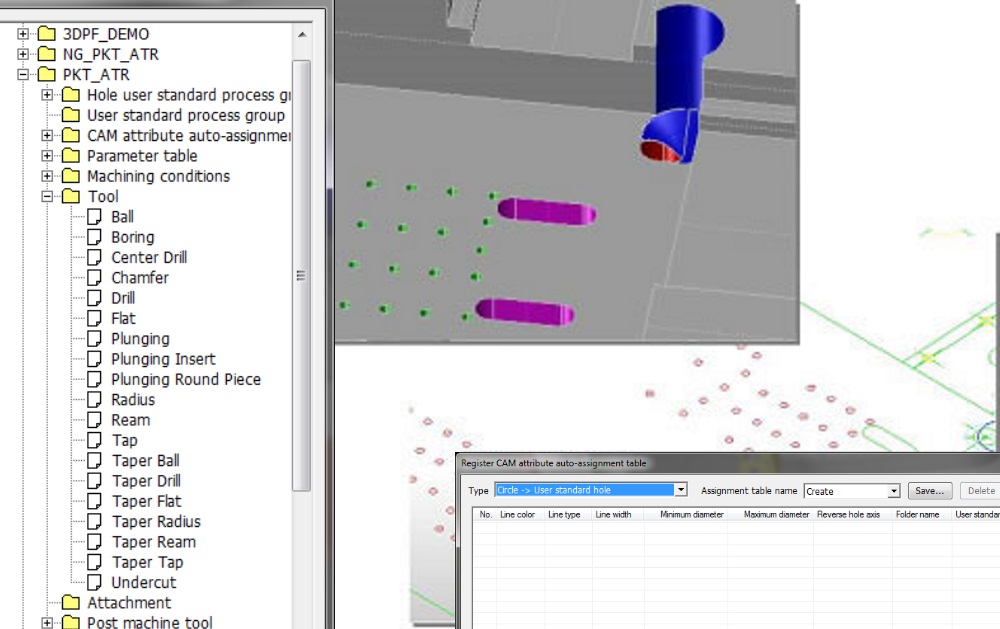

Tables that describe conditions for creating hole-machining data can be created by a special GUI tool.

Machining expertize can be standardized by combining individual Tables.

UEL (Thailand) Co.,Ltd.