CAM-STL

CAM-STL in conjunction with CADmeister/CAM creates paths on the basis of STL figures. It supports a reverse-engineering type of machining. It is capable of drawing data from STL figures such as measurement results and from models consisting of surface data and solid data, and then creating paths for rough machining and finish machining, checking interferences, and outputting NC data.

Features

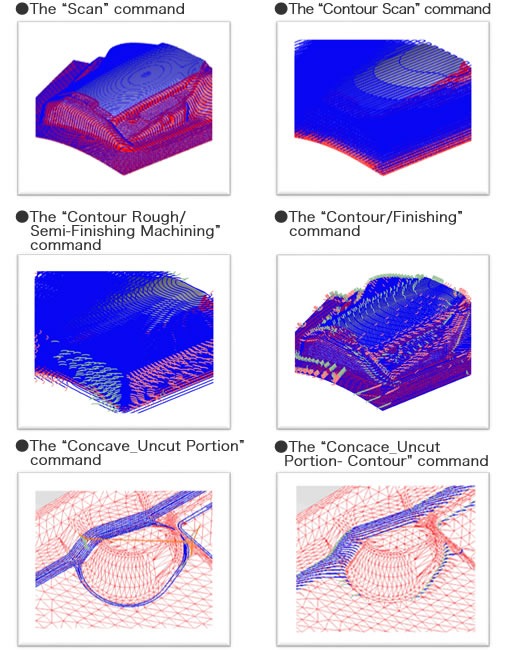

Types of Machining Phases

Paths without causing interferences can be created for the phases of rough machining, finishing, and making corners.

- Types of Machining

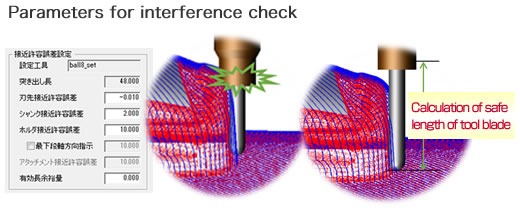

Functions for Checking Interference

Any interferences between STL figures (possibly also comprised of surface data) of models and materials can be checked. Also, interference check can be made between tool shanks and shank holders, under the condition that their existences are made to expand by indicating a value of approach tolerance. The shortest length of ejection can be calculated based on the check results. Also, path segmentation is enabled by considering any possible interferences caused by a holder, provided that multiple tool candidates have been indicated.

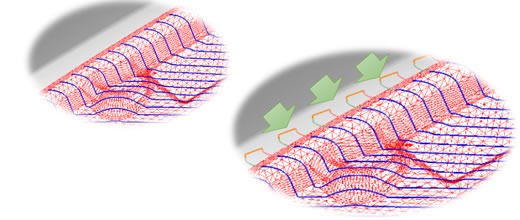

Addition of Blade Movements (excl. Cutting)

Blade's non-cutting movements of approaching, retracting, and pick feeding can be corrected after editing paths. Efficient corrections are enabled by checking any interferences caused by a blade against STL figures of models (possibly also consisting of surface models), and then adding again the blade’s non-cutting movements of approaching, retracting and pick feeding.

Inquiries

If you have any inquiries about our product or would like to request a visit to your place for explanation or demonstration, please use the inquiry form.

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

EN

EN

TH

TH

IN

IN

VN

VN